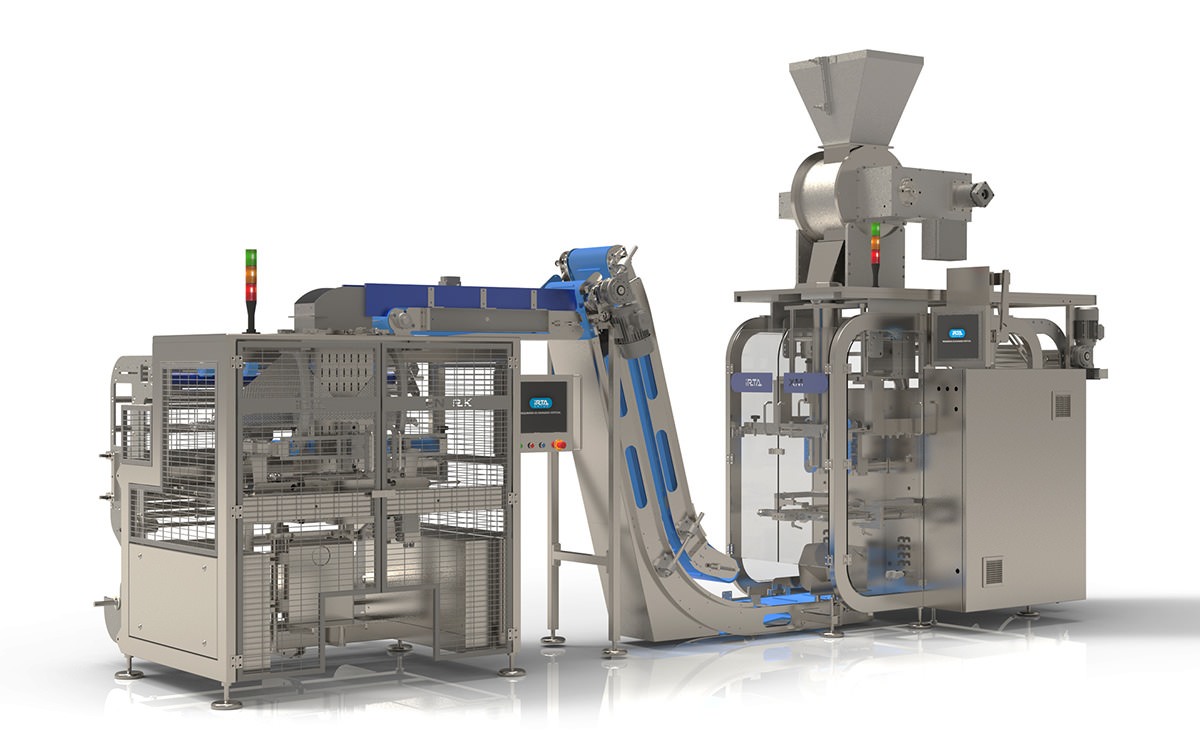

The vertical bagging machine IRTA RK is specially designed for bagging large bags in very short space. The automatic bagging machine Irta Rk occupies only 2.7 m².

It produces bags with handles or large capacity bags (up to 60 x 30 cm). 2 different bag shapes with a wide range of dimensions pre-set as standard to produce bags with and without handles.

Multi-format bag and sack bagger for resource optimization

Large-format bags and sacks for packaging FMCG products, which have a fast shelf turnover, are becoming increasingly popular.

Including a larger quantity of product in the packaging has associated advantages such as reduced packaging times, energy consumption and the amount of plastic used in the process. All this translates into lower production costs, lower CO2 emissions and less waste. In short, the optimization of resources with a lower environmental impact.

Allows the product to be bagged in pillow o pillow with a stable bottom.

BAGS WHICH THEY MANUFACTURE

Block Bottom Bag – EN-SACK

Block Bottom Bag – Handles

Pillow-pack – Handles

BAGS WITH HANDLES UP TO 20 Kg

Depending on the product and the material used for its realization.

The possibility of making large capacity bags with handles that facilitate their transport adds an extra component that can be decisive in the purchase decision.

DIMENSIONS

Adjustable width: 50 mm – 500 mm

Adjustable length: 100 mm – 700 mm

Designed for packaging large volumes of product.

Ice

Snacks

Animal feed

Aggregates

Pastries/Bakery

Flake ice

Stand Up

Our qualified personnel travel to the end customer’s workplace to fine-tune the packaging machine and initiate production. On-site training courses are also provided to the staff responsible for the packaging process.

Maintenance

We have basic maintenance packs for the parts that suffer the most wear and may require stops of the vertical packaging machine, in this way the operator himself can solve the problems without requiring technical assistance.

Technical assistance

Technical support is a fundamental pillar within the company’s structure and the customer-manufacturer connection. IRTA Group allocates a significant portion of its resources to this department, where, to a large extent, customer satisfaction depends.

Request information

SPECIFICATIONS

- Machine finish: Stainless steel

- Max. output: 50 Cycles/min.

- Power consumption (Max. rated value): 5.5 KVA

- Mains connection: 230 / 400 Vac

- Type of protection: IP 55

- Servomotors: Rockwell

- Pneumatics: Festo

- Vacuum pump: Becker

- Air consumption: 12 Nl / Cycle

- Management of movements and field elements: Ethernet bus.

- Axis control. Motion functions implemented: Yes

- Soldering temperature, time and pressure regulation on screen: Yes

- Coil. Width / Max. diameter: 1,100 / 420 mm

- Reel mandrel: 75 mm

- Film drive: Vulcanized roller

- End of film pre-warning: Yes

- Quick reel change, with or without suction: Yes

- Quick and easy change of all parameters: Yes

- Color touch screen display: 10

- Interface languages: ES / EN / DE / FR

EXPANSION KITS

- Printed film centering system

- Modified atmosphere injection

- Constant heat grippers

- Motorized film unwinder with screen-controlled film tension control

- Automatic web centering, “Autotracking”.

- Film static current elimination

- Bag vibrator

- Euro-lock / Eurohole

- Coders, labelers ...

- Product evacuation conveyors

- Ethernet LAN connection